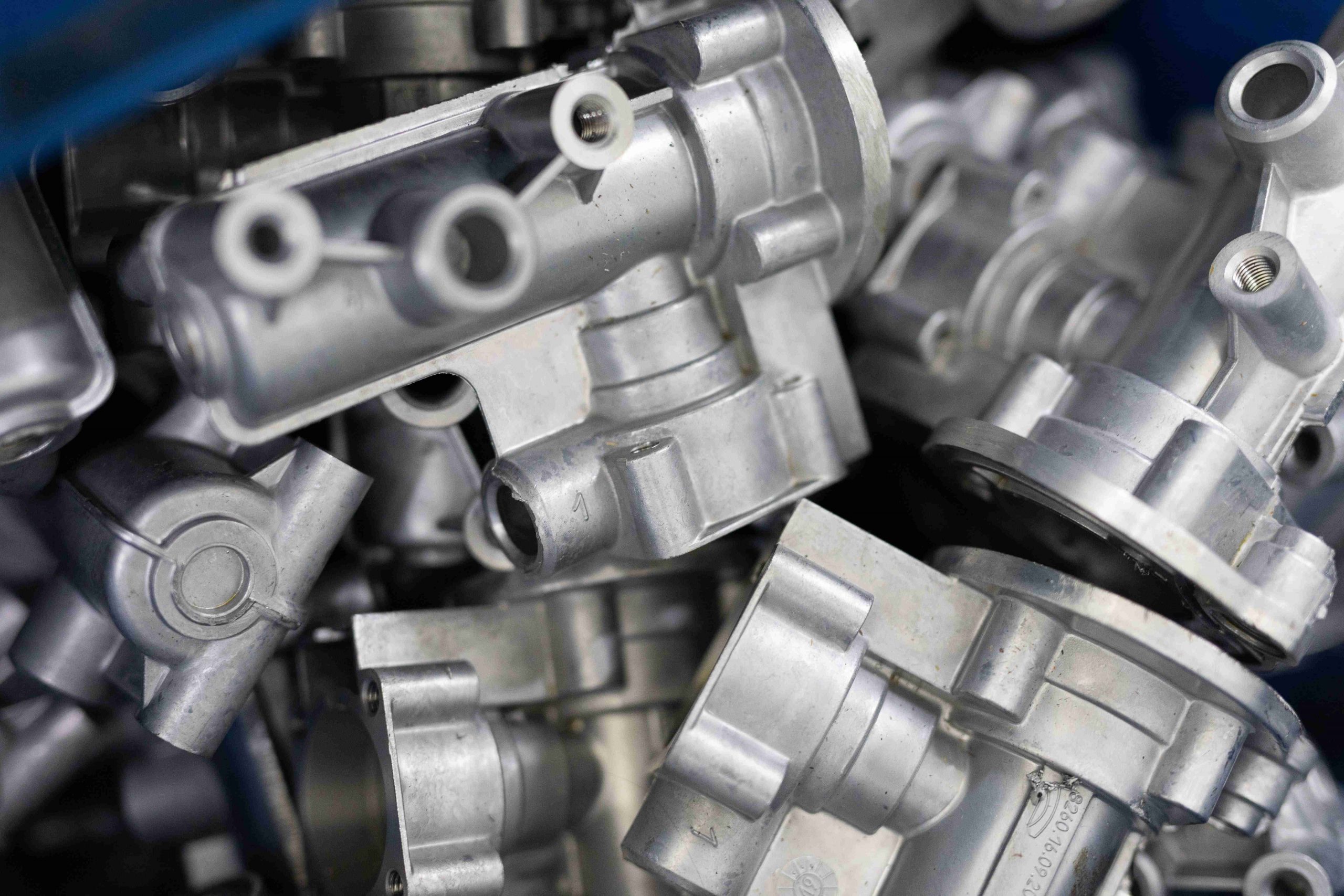

Die Casting

When our customers require us to produce high volumes of relatively complex metal parts, then we resort to die casting to enhance the versatility, accuracy, and reliability of the metal components. At Axionray, we are well equipped in die-casting parts that can be of exceptional use in industries dealing with automobiles, lighting, power equipment, aerospace components, etc.

Axionray advantage - what is special about our die-casting techniques

At Axionray, we die-cast components in different metal alloys, such as copper, brass, aluminum, zinc, and bronze. We will not just stop with the die casting of the component but will also refine it with the help of CNC machining. We also apply surface finishing through exceptional processes like texturing, plating, shot-blasting, painting, etc.

With our in-house expertise in handling tool designs and our knowledge in making use of industry-leading software and mold-flow analysis tools, we ensure to produce very high-quality die cast parts for our clients. At Axionray, we support both short-run batch and high-volume production with the help of soft tooling techniques. You only have to submit your requirements through drawing and 3D files and leave the rest to us.

Talk to our engineering expert.

Applications and advantages of die casting technique

Die casting offers vitality to the metal components, and it also enhances high production, thus making it the best fit for diverse industries and applications. Die casted products, in small to medium sizes, are of exceptional use as industrial and consumer products and as parts in medical devices. It is also a procedure of choice when high-volume metal parts are required for processes such as metal injection molding.

It holds complex geometry

With the help of die casting, it is possible to produce reliable custom die-cast parts with thin walls. Though they hold challenging geometry, they are durable and are also dimensionally stable.

It holds superior strength

Metal die castings are stronger than plastic injection molded parts. They are also resistant to very high temperatures. When metals like aluminum are subjected to die casting, they offer exceptional strength-to-weight ratios.

The parts carry exceptional precision

The typical metal tolerance of die-casted metals ranges from 0.003 to 0.005 per inch but can also go up to 0.001, depending on the customer’s specifications and the material.

Custom finishes

It is possible to attain custom finishes with die casting. The cast parts can be made smooth and textured or with plating and paint finishes. These finishes will help protect from corrosion.

World-class die-casting techniques

At Axionray, we make use of high-quality and the latest die-casting machines and technology to offer high-quality and on-demand parts for a variety of industries. We generally focus on two leading die-casting types, namely hot chamber casting and cold chamber casting. Both these types of casting are capable of producing parts with complex geometry and with exceptional mechanical properties.

We also employ gravity die casting, high-pressure die casting, and low-pressure die casting techniques to support permanent and semi-permanent casting processes. Our experts will choose the machine tonnage based on several factors, such as part size and cavitation. We offer casting in a range of materials, such as aluminum alloys, brass, copper, zinc alloys, and magnesium. Apart from die casting, we also perform secondary operations on the die-cast parts, such as surface treatment and finish machining.